OFA and FGR for Emissions Control on Stokers

CC&E engineers have experience designing and installing a combined overfire air (OFA) and flue gas recirculation (FGR) system for stoker boilers for the reduction of NOx, CO, and flyash emissions. CC&E personnel have provided this combined system to multiple stoker boilers, conducting baseline testing, CFD modeling, system design, system installation, tuning, optimization and commissioning.

CC&E engineers have experience designing and installing a combined overfire air (OFA) and flue gas recirculation (FGR) system for stoker boilers for the reduction of NOx, CO, and flyash emissions. CC&E personnel have provided this combined system to multiple stoker boilers, conducting baseline testing, CFD modeling, system design, system installation, tuning, optimization and commissioning.

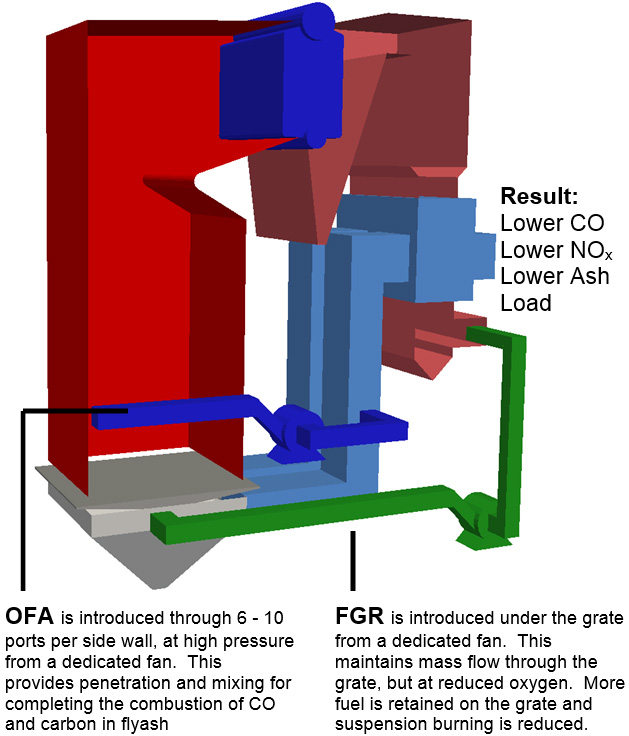

The combined system takes advantage of several complimentary effects. The OFA component employs 6 to 10 ports along the side wall, at high pressure using a dedicated fan. This arrangement provides penetration and mixing of the air, to ensure CO and char burnout. By diverting the air for the OFA from the undergrate duct, the system lowers O2 at the grate elevation, delays final combustion, and reduces NOx production.

The FGR component replaces the diverted undergrate air with recycled flue gas. This maintains mass flow through the grate, keeping the grate combustion cooler and avoiding hot spots. The FGR dilutes the oxygen concentration at the grate elevation, contributing to reduced NOx formation.

System Design & Supply

The OFA + FGR system is dependent on injecting the OFA at the right location to achieve the optimum combination of delaying combustion to reduce NOx and rapid final mixing to ensure CO and char burnout. CC&E starts the design process with an extensive baseline testing program to collect key operating data and identify the optimal OFA port locations for multiple boiler loads across the operating range.

Our testing crew will collect flue gas, O2, CO, NOx, and temperature data across the boiler operating range. Data is collected in the high temperature furnace region data with water-cooled probes, as well as at the furnace exit with multi-point sampling grids.

Our testing crew will collect flue gas, O2, CO, NOx, and temperature data across the boiler operating range. Data is collected in the high temperature furnace region data with water-cooled probes, as well as at the furnace exit with multi-point sampling grids.

This baseline data is used to validate CC&E’s full furnace CFD model. The CFD model is essential in determining the quantity and placement of OFA ports to insure the best system performance.

CC&E engineers work closely with plant personal to design and specify all components of the OFA + FGR system.

CC&E provides installation support and onsite startup to insure a correct and timely installation of the combined system.

Our engineers and technicians conduct an extensive optimization test program to achieve maximum system performance.

CC&E completes the system supply with detailed training sessions for both operating and maintenance personnel.